In the world of modern medicine, technology continually pushes the boundaries of what’s possible.

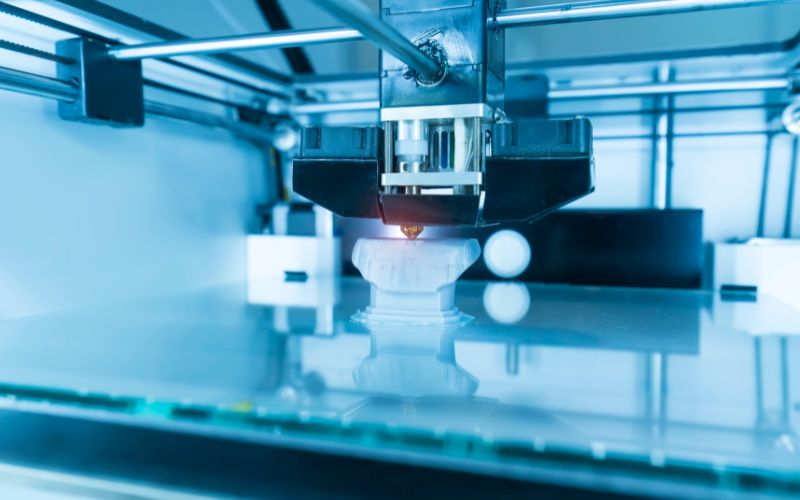

One such innovation that has been making significant waves in recent years is 3D printing, also known as additive manufacturing.

While 3D printing has found its place in various industries, its applications in healthcare are both modern, and also have proven so far that they have enormous potential.

From crafting prosthetic limbs that fit like a glove to bioprinting organs for transplantation, the possibilities have grown and grown.

In this blog, we’ll discuss the history of 3D printing in medicine, exploring its fundamentals, diverse applications, remarkable case studies, and its potential to shape the future of healthcare.

Understanding 3D Printing in Medicine

At its core, 3D printing is a process that creates three-dimensional objects by layering materials on top of one another, guided by a digital model.

This layer-by-layer construction sets it apart from traditional subtractive manufacturing methods, where material is removed to shape the final product. In medicine, this innovative technology enables the creation of intricate and patient-specific devices and structures.

Types of 3D Printing Techniques:

There are several 3D printing techniques in use today, each with its own strengths and applications.

Among the most prevalent are Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). These methods differ in terms of the materials they use and the precision they offer, making them suitable for various medical applications.

A Glimpse into History

While 3D printing may seem like a cutting-edge technology, its roots trace back to the 1980s when Chuck Hull, an American engineer, invented stereolithography.

Since then, it has been an exciting journey of technological advancement. Over the years, 3D printing has transformed from a niche concept to a versatile tool that touches nearly every corner of the medical field.

Patient-specific implants are a big part of this shift. With 3D printing, we can custom-make implants to fit someone’s unique anatomy.

This isn’t just about better functionality; it’s about giving people a higher quality of life, especially in areas like orthopaedics and dentistry.

Examples of 3D Printing in Action

3D printing is transforming medical practices with its versatile applications, revolutionising traditional approaches and sparking innovation. Here are some key examples:

Bioprinting Tissues and Organoids:

Bioprinting is a groundbreaking use of 3D printing in medical devices. Unlike conventional methods employing plastic or metal, bioprinters use a computer-guided pipette to layer living cells, or bio-ink, constructing artificial living tissue in a controlled lab setting.

This method has significant implications for medical research, providing miniature-scale replicas of organs known as organoids.

Organovo, a US-based medical lab, is actively experimenting with bioprinting liver and intestinal tissue. These tissues serve as valuable tools for studying organs in vitro and for drug development, offering potential alternatives to traditional human organ transplants.

This technology holds promise in addressing conditions like type 1 tyrosinemia, as demonstrated in Organovo’s pre-clinical data for the functionality of its 3D-printed liver tissue.

Surgery Preparation with 3D Printed Models:

3D printing is a game-changer in surgery preparation, enabling the creation of patient-specific organ replicas. Surgeons use these replicas to practice complex procedures before actual surgeries, speeding up procedures and minimising trauma for patients.

In Dubai, the Health Authority has inaugurated a 3D Printing Lab within its Innovation Centre. This facility aims to furnish medical professionals at DHA with patient-specific anatomical models, facilitating detailed preoperative analysis.

The implementation of 3D printing technology enhances the capability of medical practitioners at DHA’s hospitals.

3D Printing of Surgical Instruments:

3D printing has expanded to produce sterile surgical instruments, including forceps, haemostats, scalpel handles, and clamps. Some instruments draw inspiration from the ancient Japanese practice of origami, ensuring precision and allowing for a smaller, more manageable size. This innovation enables surgeons to operate on delicate areas with minimal additional damage to the patient.

The use of 3D printing for surgical instruments not only ensures sterility but also significantly reduces production costs compared to traditional manufacturing methods.

Custom-Made Prosthetics Using 3D Printing:

In prosthetics, 3D printing has revolutionised the production of custom-made limbs. Traditional prosthetic manufacturing can involve lengthy waits, but 3D printing accelerates the process, delivering cost-effective products with the same functionality as conventionally manufactured prosthetics.

This approach is particularly beneficial for children who quickly outgrow their prosthetic limbs.

Patients can actively participate in the design process, thanks to innovations like Body Labs’ system, allowing them to model prosthetics based on their limbs through scanning for a more natural fit and appearance.

In summary, 3D printing in medicine is not just a technological advancement but a transformative force. From patient-specific implants to bioprinting tissues, its applications are diverse and impactful.

As 3D printing continues to evolve globally, the future of healthcare looks promising, with personalised treatments and enhanced precision becoming the norm.